The length-based HD data store primarily applies to plants or processes for the manufacturing of long products with limited lengths, as e.g. in rolling mills for the metal industry. The samples will not be assigned to the time axis, but to a length axis that corresponds to the length of the product. In the display (HD trend graph), the samples will be plotted over a length axis instead of the time axis. The objective of the storing and display type is to correlate samples to the product length, so that a statement about the value of a measured signal on a specific point of the product (length or distance measured from the beginning of the product) can be made.

Other applications for the length based data store are measurements of moving objects such as cranes, winches or vehicles to display the samples on the traverse distance, for example.

Measuring locations have to be defined for the data storage in order to correlate the measurement signal and the length geometrically. A measuring location is a point that is passed by the product (measurement medium) and where measuring signals are created. Depending on the required accuracy at the assignment of the signals to be measured and the length of the product (selection of the storage profile) you have to define several measuring locations, if the samples (sensors, system parts) are spatially separated.

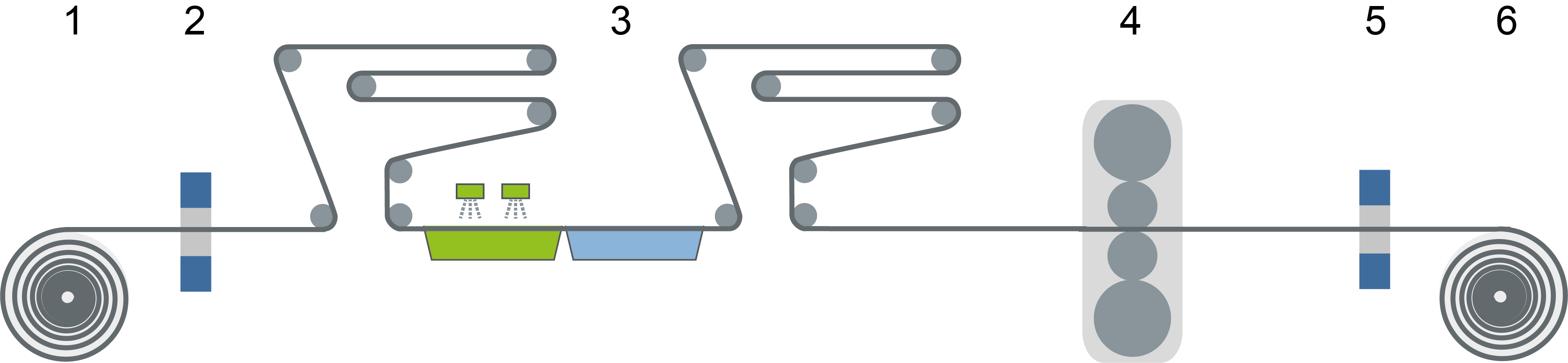

The following figure shows an example of a simplified plant with 6 areas, where measuring data are created.

6 measuring locations with corresponding measuring signals are defined accordingly.

|

No. |

Measuring location |

Signals to be measured (example) |

|---|---|---|

|

1 |

Pay-off reel |

Strip tension, speed |

|

2 |

Thickness gauge entry |

Strip thickness entry |

|

3 |

Cleaning |

Temperature, concentration |

|

4 |

Skin pass mill / rolling stand |

Roll force, skin pass degree, strip tension entry, strip tension exit |

|

5 |

Thickness gauge exit |

Strip thickness exit |

|

6 |

Tension reel |

Strip tension, speed |

The configuration of the measuring locations and the assignment of the signals will be made at the configuration of the data storage.

For more information about this, see chapter Configuring length-based data store

The calculation of the length will be automatically effected by a speed signal.

In an HD trend graph view only length-related signals of the same measuring location can be shown. Related to the above mentioned example, this would mean that the length-based display of rolling force and skin pass degree can be made in one HD trend graph view and the display of the strip thickness exit in another.

Unlike the time-based display, no multilevel aggregation of the measuring values for the data store will be made during the length-based storage. The raw data will only be stored according to the selected storage profile.

Therefore, 1 value of samples per meter will only be stored in the HD principle at for example a length base of 1 m.